USGS Mineral Summary January 2015-Cement Section

Cement production and consumption in the United States

Cement production and consumption in the United States: Domestic cement production in the United States increased in 2014, with 97 cement plants in 34 States producing 80.5 million tons of Portland cement and 2.2 million tons of masonry cement. Two cement plants in Puerto Rico also produce cement. Cement production remained below the peak of 99 million tons in 2005. Several cement plants continued to shut down their kilns. Many other cement enterprises could not fully develop their production capacity. In recent years, some cement plants have closed down. Cement sales increased significantly in 2014, but were lower than record high of 41 million tons in 2005, with overall sales of about $8.9 billion. Most of the cement is used to make concrete, which is worth at least $48 billion. In recent years, about 70% of cement sales have gone to ready-mixed concrete companies, 11% to concrete products companies, 9% to construction contractors (mainly pavement construction), 4% to oil and gas well construction, 4% to building materials dealers, and 2% to other uses. Texas, California, Missouri, Florida and Michigan are the top five regions of cement production in the United States, accounting for 53% of the total production in the United States.

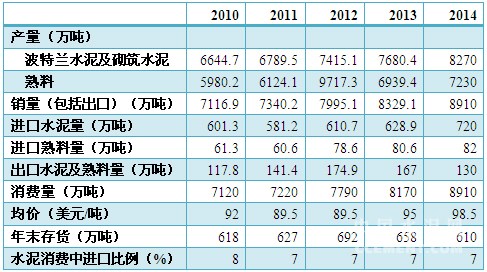

Table 1: Cement production and consumption in the United States in recent years

Recycling economy: The dust produced by excess cement production is routinely recycled to the clinker production process, while the clinker production process can also use a series of raw materials and fuel wastes, such as slag and fly ash. Different auxiliary materials can be recycled as admixture in composite cement and concrete. Concrete can not directly recycle cement, but can focus on recycling building aggregates.

Cement import source countries and proportion (2010-13): Canada-51%, South Korea-18%, China-8%, Greece-5%, other countries-18%.

Trends & Issues: Cement sales continued to grow in 2014 due to higher demand for new residential construction and non-residential construction. Public sector construction investment is relatively weak, but it is expected to gradually increase with the increase of tax revenue. Imports of cement increased, but several major cement import terminals remained idle. Cement production is still well below capacity, with some cement plants with multiple kiln lines having only one kiln line in operation in 2014. No new production lines were built in 2014, and some cement plants are being upgraded, including the conversion of wet kilns to new more energy-efficient dry kilns. In 2014, no cement plant announced its closure, two of the world's largest cement companies announced their merger, and the world's largest cement company will be born.

Cement production of various countries in the world

The production process of cement clinker releases a large amount of carbon dioxide. The main purpose of the carbon dioxide reduction strategy of the cement industry is to reduce the carbon emissions per ton of cement products, rather than carbon emissions of cement plants. Carbon reduction methods include the installation of more efficient burning systems, partial replacement of clinker raw materials with non-carbonated raw materials, and partial replacement of cement in cement products and concrete with mineral admixtures such as pozzolans. The use of mineral admixtures and the use of inert additives or extenders can reduce the unit cost and carbon emissions of cement raw materials in concrete because mineral admixtures do not require an energy-consuming combustion preparation process. The standard ASTM C-595 (American Society for Testing and Materials for Cement, Ceramics, Concrete, and Masonry) allows the addition of up to 15% limestone to the admixture for composite cements, but the widespread use of limestone is still not significant as of 2014. The research and development of cement varieties with lower energy consumption than Portland cement and low-emission raw materials are still continuing.

Air pollutant emission standards originally required cement plants to meet emission standards in 2010, but the implementation time of emission standards for the entire cement industry was postponed to 2015. Previous emission standards have been significantly lower than acceptable levels of mercury and other pollutants. Some cement plants have been equipped with mercury purification technology, but it is not clear how many can afford this technology. Mercury emission limits were expected to make it difficult for cement plants to continue to use fly ash as a raw material in clinker production.

Table 2: Cement Output and Capacity of Countries in the World (10,000 tons)

Global resources: Although individual plants are understocked, cement raw materials, especially limestone, are widely distributed and abundant, and overall there is unlikely to be a risk of shortage in the future.

Substitutes: The vast majority of Portland cement is used in the production of concrete and mortar. Substitutes for concrete in the construction industry include asphalt, clay bricks, rammed earth, aluminum, fiberglass, glass, steel, stone, wood, etc. Many raw materials, such as fly ash and granulated high alumina slag, have good hydraulic properties by reacting with lime released by cement hydration. These mineral admixtures are increasingly used in concrete construction in areas where supply is not limited, as a partial substitute for cement, and increasingly as a component of composite cement.

浙公网安备33010802003254号

浙公网安备33010802003254号