According to a 2014 USGS study, there are two cement plants in Afghanistan, both located in the Pol-e-Khomri district of Samangan province:

Ghori I Plant : two kilns, with a clinker production capacity of 400t/d; during the reporting period, Ghori I Plant was in an intermittent operation state due to the limitation of coal acquisition.

Ghori II plant : two kilns with 1200t/d clinker production capacity. According to the Global Cement Yellow Pages, Ghori II has not been completed and is not producing cement at present.

The third plant, Ghori III, has a clinker capacity of 4,000 t/d and was originally planned to be commissioned in 2013. However, the Global Cement Yellow Pages confirms that construction of the plant has not yet begun. All Ghori Cement plants are owned by Afghan Cement LLC, a subsidiary of Afghan Investment Company (AIC), which until recently was owned by Mohammad Karzai, the brother of former President Karzai, and other wealthy investors with ties to the government.

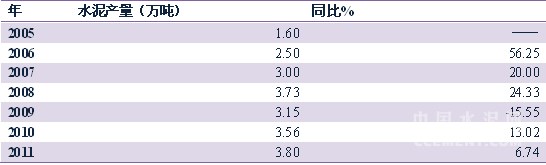

According to the USGS 2012 Mineral Yearbook, the latest data show that Afghanistan produced 37,000 tons of cement in 2012, down from 38,000 tons in 2011, but up from 35,600 tons in 2010. In May 2013, the domestic cement demand is expected to be 7 million tons. From 2009 to 2010, the domestic annual demand for cement is estimated to be 6 million tons.

Table 1: Cement production in Afghanistan from 2005 to 2012

Source: USGS

As there is only one operating cement factory in Afghanistan, many factors besides the national economy will affect its operation. According to a 2012 report by the Afghan Ministry of Mines (MoM), Afghanistan's cement production is the lowest in the world, with only 2 kilograms per capita. This is very low, such as 92 kg/person in Pakistan and 200 kg/person in the United Kingdom.

Cement plant not in operation

In September 2013, MoM issued a tender for the construction of new cement plants in the Jabal-ul-Saraj district of Parwan province and the Pol-e-Khomri district of Samangan province, and for the completion of part of the plant in the Injil district of Herat province. In cooperation with the US Department of Defense and with the technical support of two foreign agencies, MoM has finalized the location of the future cement plant. The proposed cement plants are expected to produce 1 million tons of cement each.

In May 2014, MoM received an offer for the construction of cement plants in Herat and Parwan provinces. Fifteen companies expressed interest in the tender, three offers were submitted and two proposals from two companies, Lego Afghan Logistic and Zasu-Honkong Union Holding, were accepted. Meanwhile, the MoM said it would tender for a closed cement factory at Jabal Saraj in Parwan province. The Jabal Saraj plant was the first cement plant in Afghanistan to install a rotary kiln. The clinker production capacity of the wet process kiln is 100t/d, which has never been upgraded since 1957. Normal production at the factory was interrupted by the Taliban in 1996. During the Taliban regime, the factory was bombed more than ten times. MoM's recent attempt to bring the Inji plant in Herat province up and running failed. In March 2013, Iran's Pesghaman Company won the bid to complete the construction of the plant and operate the Inji plant. In 1978, the Inji plant began construction with a capacity of 3000t/d, but the construction was delayed after the outbreak of the civil war and was not completed. The contract with Pesghaman Company was terminated because, according to MoM, Pesghaman Company could not install the required capacity within 27 months. This is mainly due to the lack of key technical and financial initiatives to tap the raw materials needed for production.

Cement import

With only one cement plant in operation, Afghanistan is severely short of domestic cement supply and has a strong dependence on imports. According to available data, Afghanistan imported 1.8 million tons of cement from Pakistan, 400,000 tons from Iran and 300,000 tons from Uzbekistan and Turkmenistan in 2005.

Pakistan is a major importer in the Afghan cement market, and most of the imported cement is supplied to the central and northern regions. 50% of Pakistan's cement exports go to the Afghan market. Among Pakistani companies exporting more cement to Afghanistan are Lucky Cement, Bestway, Cherat, Lafarge, Fauji Cement and DG Khan Cement. Among them, 30% of the total export volume of DG Khan Cement and 20-25% of the total export volume of Lucky Cement go to the Afghan market.

However, in recent years, the export of cement from Pakistan to Afghanistan has been significantly reduced, from 4.73 million tons in 2010-2011 to 3.66 million tons in 2013-2014. In the first six months of fiscal year 2014-2015, 1.66 million tons of cement were exported to Afghanistan, which is 1/2 of the same period in fiscal year 2013-2014. Exports were 441,000 tons in July 2013 and fell to 184,000 tons in June 2014, mainly due to the North Atlantic Treaty Organization (NATO) preparing to leave Afghanistan. NATO accounts for most of Afghanistan's need for cement, which it uses to build military bases and rebuild. Once NATO forces leave Afghanistan, the demand for cement in Afghanistan will become unstable and will depend more on whether the country is stable or whether the government continues to develop its plans.

Huge cement imports are a challenge for Afghan cement producers, while Iran's cement production is heavily subsidized by the government, resulting in low prices in domestic and export markets. Iran is one of the largest cement producers in the world, exporting more than 20 million tons of cement in fiscal year 2013-2014. The cement industry in Uzbekistan, Tajikistan and Turkmenistan is expanding its production capacity and will export a large amount of cement to Afghanistan in the future. In Pakistan, many cement factories are modern energy-saving factories, which can save production costs. Pakistan's cement producers sell their products abroad, including in Afghanistan, at lower prices than they can get at home.

浙公网安备33010802003254号

浙公网安备33010802003254号