Over the past five years, Professor Xu Weiguo of Tsinghua University and his team

have successively "printed" a bridge, a bookstore and several parks with the technology

of "robotic 3D printing concrete".

He also made a house for a post-70s rural couple-

"printing" only 160 hours, more than 200000 costs,

the only one in the country.

_ h720.013

Robots, "Printed" a House

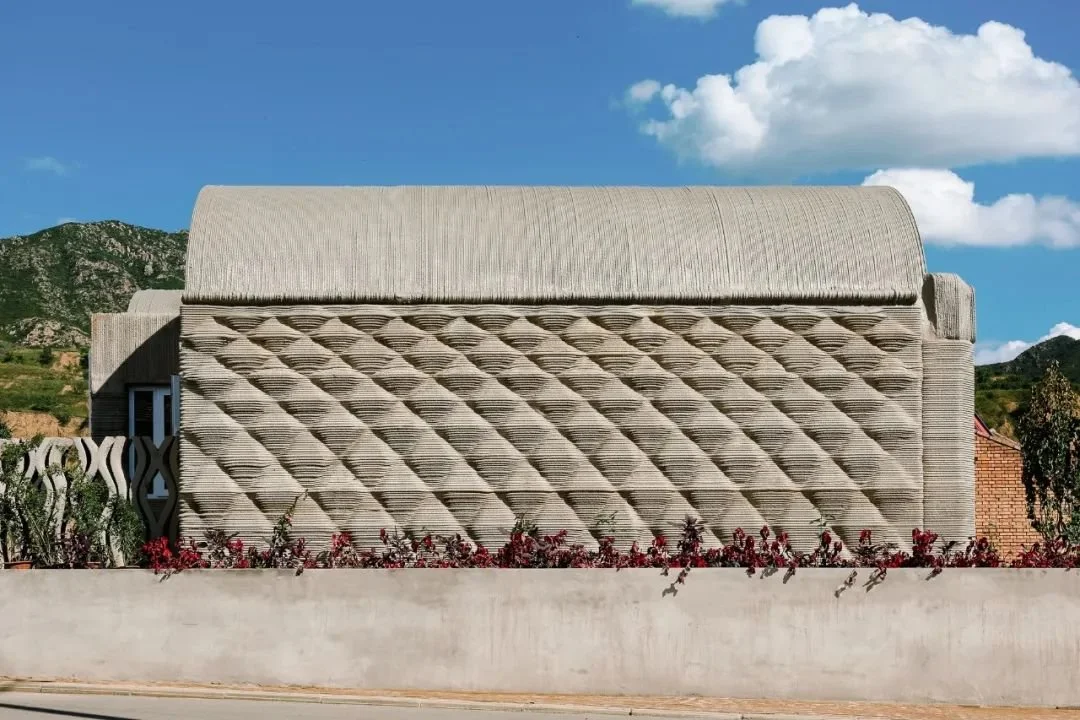

in Rural Hebei The farmhouse where Juanzi lives, 106 square meters, is the first house built entirely by "3D concrete printing" in China.

The residence is located on the side of the village road in Wujiazhuang Village, with arched roofs and gray walls, which are particularly conspicuous among the simple farm houses with brick and earth colors. On

this ancestral homestead, the old house was built with bricks and wooden roofs.

One year the Spring Festival, Xu Weiguo went into the village to investigate, "The wind blows directly into the house from the cracks of windows and walls, and the indoor temperature is very low."

wall, between the decoration surface and the wall, is hollow and filled with foam insulation materials to meet the requirements of energy saving.

The whole building is very strong, cold in summer, warm in winter, and has withstood seismic tests.

The new house was completed less than a year ago, but people who wanted to visit Juanzi's house were already in her row, "and some people asked me if I wanted to change it into a homestay.".

Juanzi and his wife, both born in Wujiazhuang in 1970, have worked outside for many years, and now Juanzi has returned to work in the village committee.

Why are you willing to try a 3D printing house that has no precedent in the whole country? Do you think the house is too outstanding?

3D printing farm house bird's eye view, Much

stronger than surrounding farmhouse Robotic concrete 3D printing process

Operated by two people, one robotic arm can start printing by itself, and three robotic arms can start at the same time. The printing nozzle at the front end of the

mechanical arm will spit out fiber concrete materials, layer by layer, starting from the foundation of the building, hitting the wall, the construction process is completed on site, once attracted the whole village to watch.

House construction period is very short, "printing" the whole process is 160 hours, about two weeks can be completed, if the future batch construction, a month, can build two houses.

Cost is also very cheap, including simple interior decoration, almost 2000 to 2500 yuan per square meter, 100 square meters of the house as long as 200000, cheaper than steel structure assembly building.

Xu Weiguo sighed, "This technology is very worthy of promotion in the construction of a large number of farm houses in China."

02

"Print" a bridge, A park

is cheap, smart, Fast

This pedestrian bridge is located in Baoshan District, Shanghai. It is 26.3 meters long and 3 meters wide. The balustrades of the bridge are streamlined and integrated.

Two 3D printing robotic arms, 450 hours, complete all concrete components. Then the components are transported to the site and assembled. The cost is only two thirds of that of ordinary bridges.

The printing material is mainly polyethylene fiber concrete with additives. It is a new composite material

independently developed by the team the intelligence of this pedestrian bridge is still there." A real-time monitoring system is embedded in the bridge, which can collect the data of the stress and deformation of the bridge in real time and help the follow-up tracking.

In 2020, the news column of Nature magazine discussed the latest progress of 3D printing technology, taking printing "bigger, faster and stronger" as three directions, including the "world's largest 3D concrete printing bridge".

Shenzhen 3D Printing Park

year," With the completion of Shenzhen 3D Printing Park, the terrain is undulating and the seats are streamlined, just like "growing" directly from the ground. Groups of curves, like valleys and streams, simulate natural forms.

The team is scattered in three places, engaged in research and development in Shenzhen, production in Wuxi, and Beijing is the office of some design members. In

the workflow, the team first builds the house in the computer, then plans the path of the robotic arm, and then converts the path into code, which is input to the control end of the robotic arm. In this way, only one or two people need to go to the printing site.

0320

, Rooted in the frontiers

of architecture In 2003, as one of the curators of the Biennale of Chinese Architectural Art, he went abroad for investigation. Traveling to the Pompidou Art Center in Paris, he was touched by an exhibition called "Non-standard Architecture". Twelve avant-garde architects

around the world, future buildings designed with digital technology, appeared in this exhibition, all of which are irregular, non-standard geometric, some in organic form, more like sculpture and art, "very different from traditional architecture".

He was very interested in the latest architectural trend of thought, and at that time he had a strong premonition that "this will be a new direction of architectural exploration".

Since 2004, five consecutive China Architecture Biennales have been held, each time with the participation of more than 50 young firms around the world, and more than 20 of the world's most avant-garde architectural schools have been invited to exhibit their students'works in Beijing. The British scholar who was invited to cooperate

at that time once told him that at present, he may be the only one in China who knows what digital design is and what algorithm design is.

"After understanding this field and plunging into it, I didn't come out," Xu Weiguo described his experience over the past 20 years. In

the first 10 years, we mainly engaged in research and gradually formed our own theory and structure system in the field of intelligent construction.

In 2017, two early students returned to China, joined his team, and began to industrialize the technology. In the past five years, they have focused on applying the technology of "robotic 3D concrete printing" to practical construction.

Xu Weiguo at work

The design questions he gave his students were also different, such as building a house on Mars.

"In retrospect, when human beings first built their homes with natural materials, the primary goal was to be economical and applicable, which is similar to the design of our Mars habitat now. It should be our visible future to use intelligent 3D printing to shape the building shell together with the interior on Mars."

"Machine intelligence is the concentration of different types of human intelligence, just as AlphaGo can defeat its opponents because it concentrates the wisdom of many people."

"The machine looks cold, but it also condenses the intimacy of different people and forms a new sense of intimacy, which is more delicate and thoughtful than a single dimension of people."

"At present, the technology of robotic 3D concrete printing is in the stage of development. If it is compared to running 400 meters, it is now running about 150 meters, and the technology is still being developed.". It will take some time for it to be fully developed to be as mature as brick-wood structure, brick-concrete structure or reinforced concrete structure.

On the other hand, Construction workers are increasingly scarce, and if robots can replace part of the construction work, leaving only a small amount of manual programming and control operations, people can be liberated from heavy manual labor.

In Xu Weiguo's view, architects do not necessarily have to make several famous landmarks, net red buildings, or win awards, "to meet the needs of the most ordinary people-this is the core purpose of our research and development of this technology." In

the past three years, 3D printing buildings have set off a wave around the world. Some cities have begun to sell 3D printing houses publicly, and the number of floors of buildings is no longer limited to single floors. Two-storey and multi-storey 3D printing houses have become a reality. A

little more imaginative, pioneer architects around the world began to experiment with new and old materials, combined with 3D printing technology, to create small buildings with novel appearance and unique experience, but also in response to post-epidemic era, people are eager to live more comfortably, clos e to nature, more energy-saving and environmental protection.

1、 Spherical 3D printed house

coordinates: Japan

square meters is sold for 3.3 million yen (about 170000 yuan), and six spherical houses have been sold out.

This year, the company also plans to launch another 3D printing "luxury version" of the house, with an area of 49 square meters, in addition to electricity, water and gas, it will also be equipped with a bathroom, easy to carry bags to check in, with an estimated price of 5 million yen (about 250000 yuan).

"Our goal is to buy a house like a car and free everyone from their mortgage."

2、 East 17th Street Residential

Coordinates: United States

this area takes only 7 days. Since its completion, These concrete print homes have withstood 7.3

, 3D printing rental

house coordinates: Netherlands

This project is the first 3D printed rental housing development in the world and the first 3D printed house for long-term living in Europe.

4、 Double-storey house

Coordinates: Germany

The special feature of this project is that it uses a new 3D printer called BOD2, which was pioneered by Danish manufacturer COBOD. In the process of printing the building structure, pipes and other internal components are added. The printing efficiency is also very high. In just five minutes, it can print a double-layer wall of 1 square meter.

5、 Curved Cabin

Coordinates: United States

The area of the house is about 90 ㎡. The architectural design is by the WATG team, a veteran international team that has been established for more than 70 years. The architectural structure uses the free-form printing process developed by Branch Tecnchology, which is a breakthrough innovation in the field of building technology. At the same time, the whole structure has zero net energy consumption.

6、 Summer Home

Coordinates: Netherlands

The room is equipped with a foldable sofa, modular decoration, which can be pulled out to become a sofa bed when needed, is a very suitable "mini residence" for seclusion in the city, and there is a 3D printing bathtub outside the house.The materials

used for printing can be completely recycled and repeatedly reprinted, which means that the whole house can be completely crushed and 100% recycled.

7、 Casa Covida

Coordinates: United States

The interior space includes a double bedroom, bathroom and central living area with a fireplace and a side cooker that is 3D printed with local clay.

This small house is a small experimental building for two people to live in, which was born in response to the needs of social quarantine after the outbreak of COVID-19.

浙公网安备33010802003254号

浙公网安备33010802003254号