Digitalization and intellectualization are the core factors affecting the long-term development of cement enterprises. The Ministry of Industry and Information Technology issued the "14th Five-Year Plan for the Development of Intelligent Manufacturing", which also clearly put forward that by 2025, more than 100 intelligent manufacturing demonstration factories and more than 10 industrial Internet platforms for key industries will be built in the field of raw materials, so as to effectively implement the national strategic plan and clearly create a new pattern of intelligent development of cement and other manufacturing industries.

With the decline of cement demand and the arrival of the peak of production capacity, the market competition is becoming increasingly fierce, and a cyclical industry shuffle is inevitable. Relying on digital and intelligent technology means, realizing technology and management upgrading, continuously reducing energy consumption, pollutant emissions and carbon emissions, and enhancing the comprehensive competitiveness of enterprises are the key for cement enterprises to meet the challenges.

China Cement Network has been committed to promoting the digital and intelligent development of the cement industry, continuously relying on huge data accumulation, building a big data platform for building materials, constantly improving the industrial big data system with big data, market information, cement index and concrete index as the core, and enabling industrial transformation with "industrial brain + digital factory".

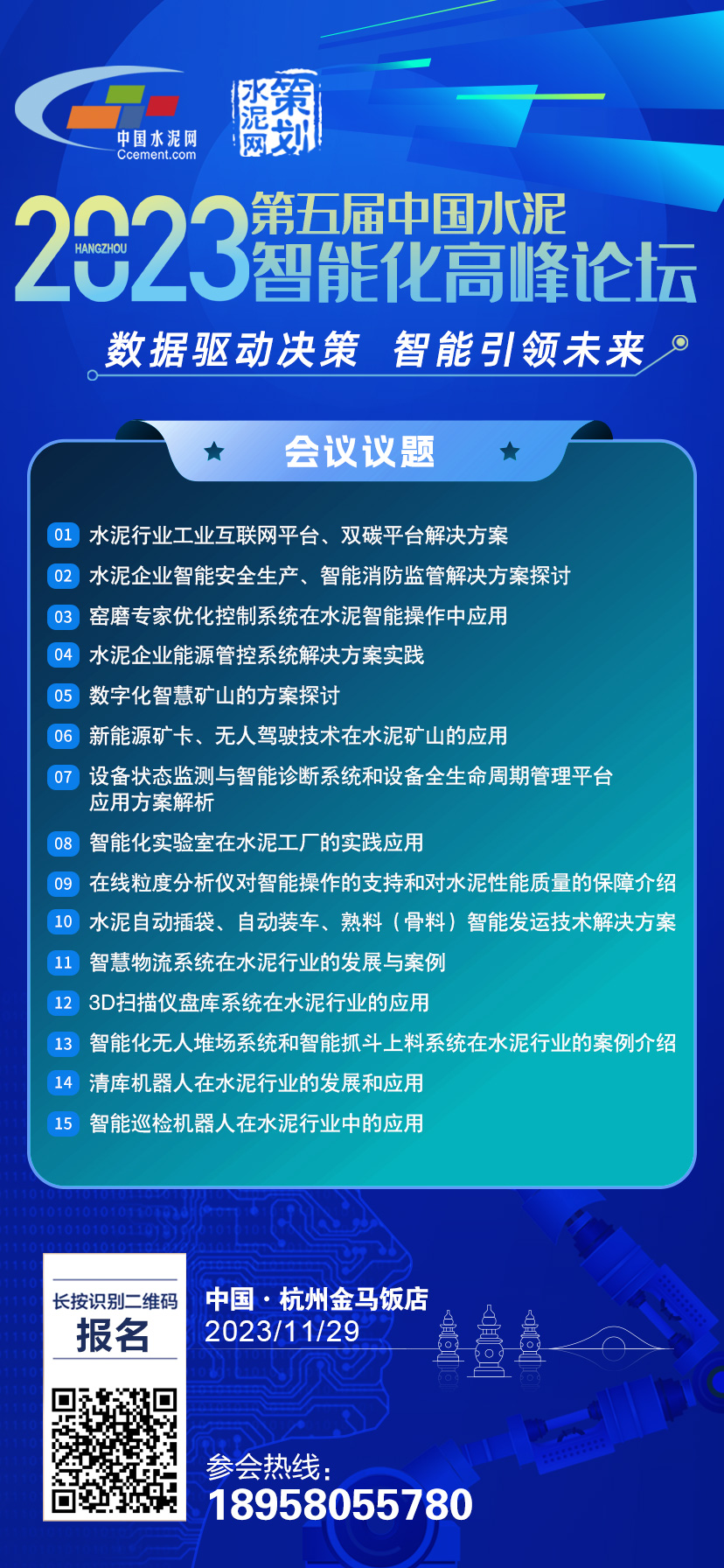

In order to gather the joint efforts of intelligent development of cement enterprises and promote new impetus for the development of the industry, China Cement Network has held four "China Cement Intelligent Summit Forum" from 2019 to 2023. Over the past five years, "China Cement Intelligent Summit Forum" has presented us with a splendid feast of industry exchanges.

Nirvana is a new milestone, winning a new journey. On November 29, 2023, China Cement Network will hold "Data-Driven Decision-Making" in Hangzhou The "Fifth China Cement Intelligence Summit Forum" with the theme of "Intelligence Leads the Future" invites industry experts, scholars and representatives of relevant enterprises to discuss and promote the intelligent process of the cement industry. Please look forward to it!

浙公网安备33010802003254号

浙公网安备33010802003254号