Recently, five scientific and technological achievements declared by China Construction Western Construction have been granted national patents.

(1) a kind of recycled self-compacting high performance concrete and its preparation method

, a scientific and technological achievement of Xinjiang Company Technology Center, a kind of recycled self-compacting high performance concrete and its preparation method, was authorized by the State Intellectual Property Office. This achievement aims at the problem of premature cracking of concrete caused by capillary expansion in the process of cement hydration, and provides a preparation method of recycled self-compacting high performance concrete. In that invention, the specific surface area of the mineral admixture is increase, the activity of the mineral admixture is improved, the gradation design is optimize, small functional materials are introduced into the admixture, the performance of the admixture is improved, the hydration proces is effectively promoted by means of chemical excitation and the like, the activity of the mineral admixture is excited, the strength and the durability of the concrete are obviously improved, and the working performance and the overall performance of the concrete can be effectively ensured. This achievement is derived from the research results of the project "Application Technology of Waste Slurry Recycling in Concrete Mixing Stations in Xinjiang", and a preparation method of recycled self-compacting high-performance concrete is prepared, which can give consideration to both good workability and pumpability, and provide convenience for construction; Under the condition of ensuring the high mechanical property and high fluidity of the high-performance concrete, the high-performance concrete has good durability and is suitable for popularization and application.

(2) a new dry artificial sand manufacturing device and its manufacturing process

a scientific and technological achievement of Guangdong Company, a new dry artificial sand manufacturing device and its manufacturing process, was granted an invention patent by the State Intellectual Property Office. Common sand making processes include wet sand making, dry sand making, and semi-dry sand making. The wet sand production process uses a large amount of water to wash, and there is no dust pollution in the production process, but it needs to consume a lot of water resources; the dry sand production process produces a high content of stone powder and dust pollution; in the semi-dry sand production process, the water content of sand raw materials entering the sand production machine is low, resulting in a low sand production rate of the sand production machine. The invention provides a novel dry-method artificial sand manufacturing device and a manufacturing process thereof, which not only can improve the sand forming rate of a crushing roller, but also can effectively control the amount of stone powder generated in the process of making sand from stone materials, and simultaneously save more water resources compared with a wet-method sand making process.

(3) An Aggregate Porosity Detection Device

a scientific and technological achievement of Xinjiang Company in Jinan area, "An Aggregate Porosity Detection Device", was granted a utility model patent by the State Intellectual Property Office. The invention discloses an aggregate porosity detection device, which comprises a sealing box for placing aggregates for detection, and a detection device connected on the box wall at one side for detecting the porosity of the aggregates. One end of a detection tube is communicated with the wall of an outer box of the sealing box, an air guide tube is fixedly sleeved on the detection tube, the other end of the air guide tube is connected with a vacuum pump, a support ring is connected on the inner tube wall of one end of the detection tube far away from the vacuum pump in a sealing and sliding manner, a filter screen is fixedly connected on the inner annular wall of the support ring, an impact component is arranged on one side of the support ring far away from the vacuum pump, And one end of that support ring close to the vacuum pump is connecte with a reset supporting assembly. The invention solves the problems of low detection accuracy and low service life of the vacuum pump in the existing concrete technology, overcomes the defects of the existing test method, automatically cleans the filter screen, improves the detection efficiency and accuracy, and ensures the service life of the vacuum pump.

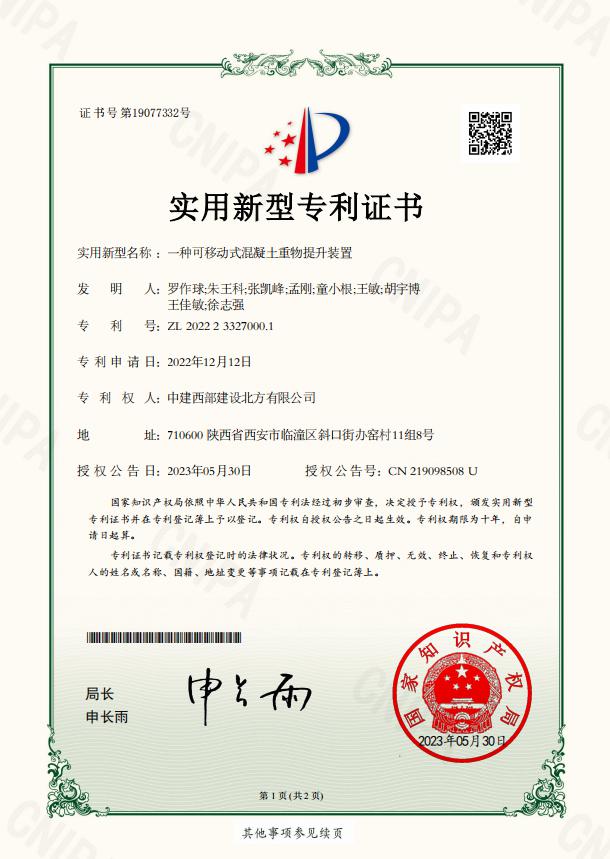

(4) a movable concrete heavy lifting device

a scientific and technological achievement of North Company, a movable concrete heavy lifting device, was granted a utility model patent by the State Intellectual Property Office. This achievement relates to the technical field of heavy lifting. Aiming at the problems that it is difficult to move the heavy concrete test block (120 kg) by hand, or even can not be placed at the designated height during the experimental test, or the safety risks are prone to occur when the concrete test block is lifted by unconventional operation, this technology combines the specific operating environment of the laboratory with the actual test requirements. A concrete heavy lifting device is developed and processed. An operator can lift the heavy object by controlling the crane and send the heavy object to a relevant designated area, so that the work intensity of the operator is reduced, the heavy object is quickly conveyed to the designated area, the work efficiency is improved, and the potential safety hazard is reduced.

(5) a pneumatic piston-type sieve aid a scientific and technological achievement of

North Company, a pneumatic piston-type sieve aid, was granted a utility model patent by the State Intellectual Property Office. In view of the characteristics of high mud content, high water content and easy bonding of machine-made sand, this achievement can not smoothly enter the scale from the sand silo, thus increasing the dangerous operation of poking the silo, affecting the production efficiency, and easily causing potential safety hazards. A pneumatic piston-assisted device is arranged on a sand bin grate, and a conical sliding block slides back and forth along a limiting groove in the vertical direction to be matched with a sand bin vibrator, so that machine-made sand is smoothly discharged, the manual bin poking frequency is reduced, the hazard source management and control are strengthened, the safety level is improved, and the safe production of an enterprise is guaranteed.

浙公网安备33010802003254号

浙公网安备33010802003254号